DELTA Robots

Delta Roboter

DELTA

Robots

What are Delta Robots

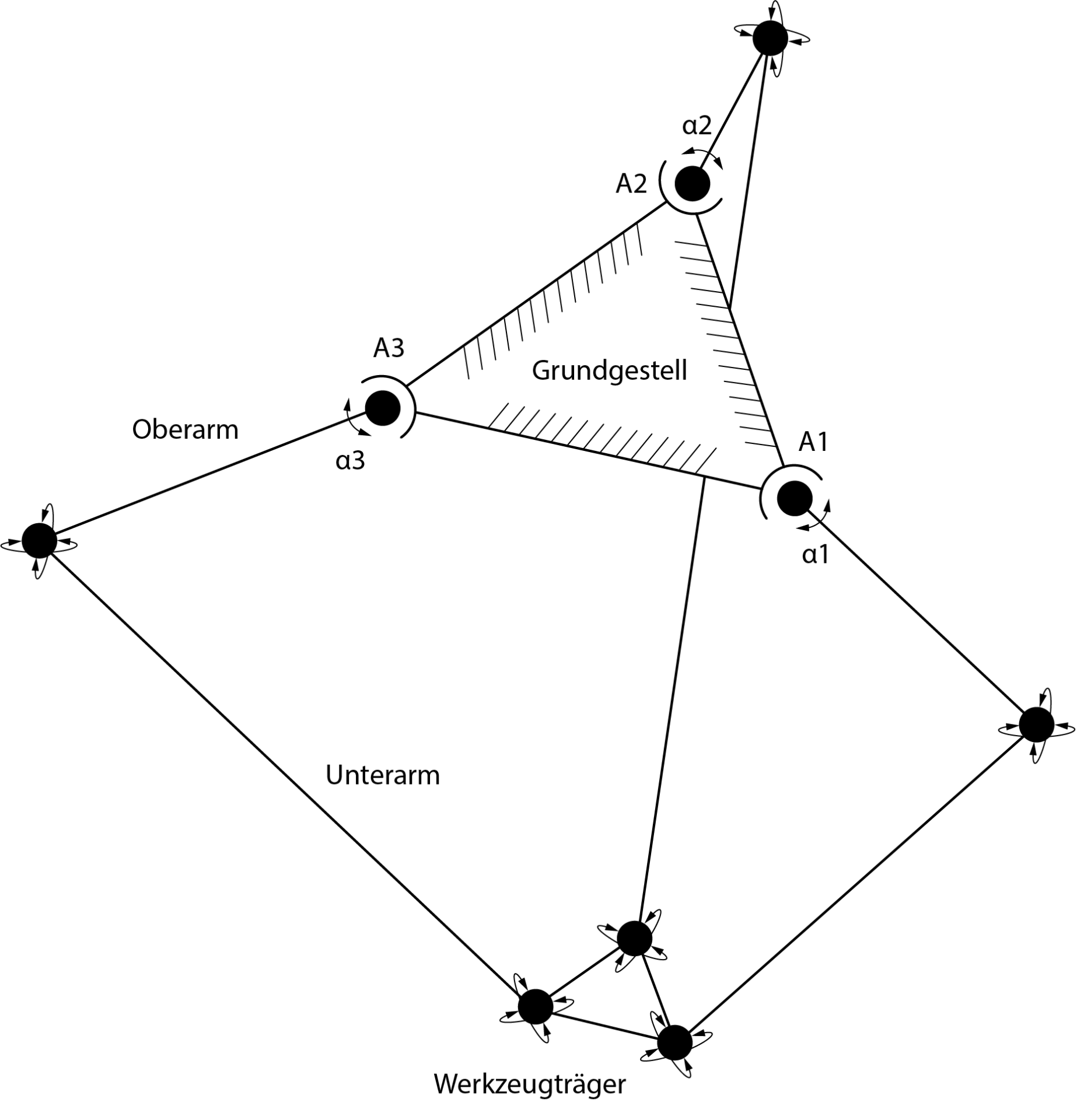

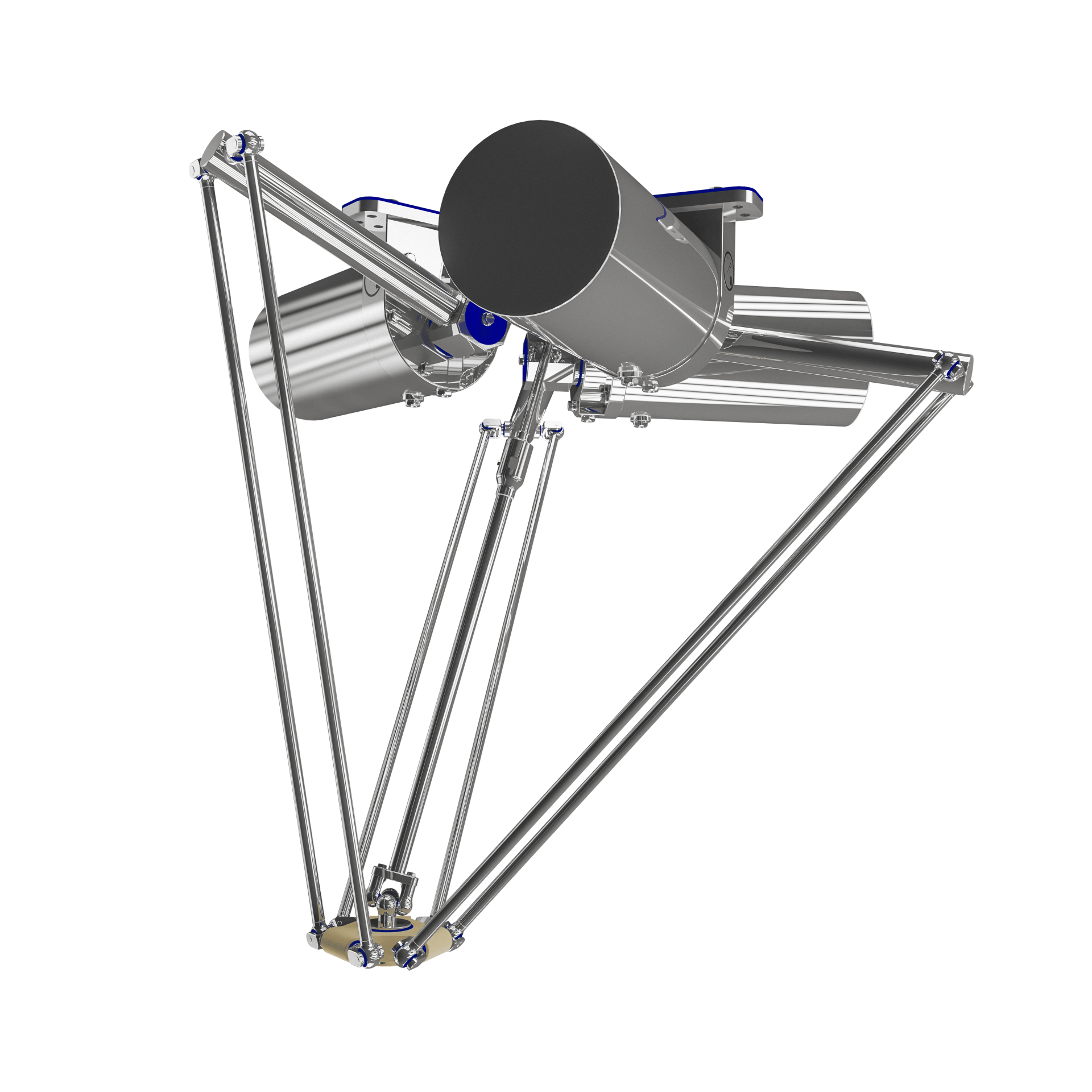

A Delta robot, is a highly dynamic parallel kinematic robot designed for fast and precise movements. Unlike serial robots, it consists of multiple parallel arms that control the end effector through a closed kinematic system. This design significantly reduces moving mass, leading to extreme speed, high repeatability, and minimal inertia.Delta robots, also known as flexpicker robots, are commonly used for pick-and-place applications, assembly processes, and packaging solutions in various industries.

How Delta Robots Work

In robotics, there are two main kinematic classes: serial and parallel kinematics. While serial kinematics consist of a sequence of arm segments, a parallel kinematic robot, such as the delta parallel robot, features multiple actuators that directly influence the moving end effector. This is a crucial advantage of Delta robots, as each drive is directly connected to the end effector, via the delta arms, eliminating the need to carry additional mass from subsequent links and drives. As a result, Delta robots excel in high-speed applications.

The low moving mass allows for extreme dynamics while maintaining high precision, making Delta robots ideal for pick-and-place tasks and high-cycle rate applications. The delta robot inverse kinematics play a key role in ensuring the efficiency of these high-speed movements.

What are Delta Robots used for

Delta kinematics is one of the most efficient solutions in modern industrial automation. Thanks to their high speed, precision, and compact design, Delta robots have become indispensable in many industries. Here are some of their key application areas:

Assembly and Manufacturing

Delta robots play a crucial role in industrial production, especially in the precision assembly of small and delicate components. Their high repeatability ensures that parts are placed with millimeter accuracy, reducing errors and improving quality.

- Precise handling of components

- Efficient automation for electronics and mechanical engineering

- High process reliability and repeatability

Packaging Industry

The pick-and-place capabilities of Delta robots make them ideal for the packaging sector. They can quickly sort, stack, and pack products—often with high-speed performance.

- Efficient sorting and grouping of products

- High-speed placement in packaging processes

- Reduction of errors in packaging operations

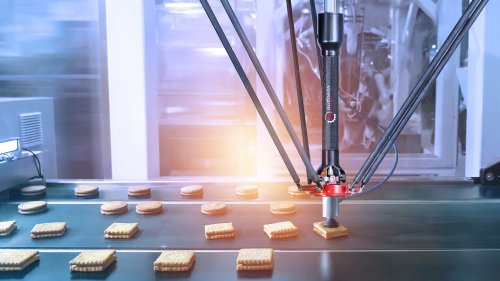

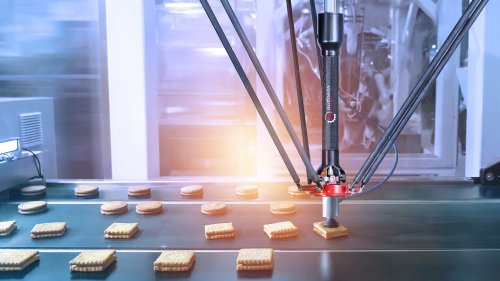

Food Industry

Strict hygiene standards must be maintained in food processing. Delta robots are often made with hygienic materials and can operate in sensitive areas without contaminating products.

- Handling delicate food products such as baked goods, fruit, or meat

- Compliance with strict hygiene regulations

- Fast processing and sorting of products

Pharmaceutical and Medical Technology

The pharmaceutical industry imposes strict requirements on safety, precision, and hygiene. Delta robots enable reliable automation in laboratories, production lines, and packaging facilities for medical products.

- Safe handling of pharmaceuticals and medical devices

- Sterile processing through contactless handling

- High precision in dosing and packaging processes

Automotive Industry

Delta robots are also becoming increasingly important in the automotive sector. Their flexibility allows them to be used in various production areas, from assembling small components to quality inspection.

- Automation of assembly processes

- High-speed placement of components

- Integration into smart production lines

Logistics & E-Commerce

With the growth of online retail, the demand for fast and efficient order-picking systems is increasing. Delta robots optimize automated order fulfillment by assembling orders at lightning speed.

- Automated order picking and sorting

- Fast and error-free order processing

- Efficient use of warehouse space

Advantages of Delta Robots

The autonox Delta robots offer numerous benefits, making them a top choice for industrial automation solutions. One of the biggest advantages is flexibility through control independence. These robots can operate with any robot controller, eliminating reliance on proprietary software or hardware solutions, giving machine builders maximum freedom in system integration. Another key feature is their high speed and precision, making delta robots for pick-and-place applications. Their parallel-kinematic design allows them to operate with extreme dynamics while maintaining exceptional accuracy.

The compact design is another significant advantage. Since these robots do not require separate control cabinets, the overall footprint of the installation is reduced, which is particularly beneficial in production environments with limited space. Easy maintenance ensures long service life. The optimized Delta kinematics design minimizes wear and allows for quick component replacement when necessary, keeping production processes stable and efficient.

Choosing the Right Delta Robot

Several technical aspects must be considered when selecting a Delta robot. The number of degrees of freedom (DoF) is crucial, with autonox Robotics offering models with 2 to 6 DoF, including 4 axis Delta robots and 6 axis Delta robots. Depending on the application, rotational ranges are also important, especially for highly precise movements. Another critical factor is the ability to perform complex trajectories, making Delta robots ideal for pick-and-place processes. They can handle payloads over 50 kg and operate in large workspaces exceeding 2,000 mm. Due to their design, Delta robots create minimal interference within the workspace, avoiding unnecessary external influences. Simultaneously, their low moving mass reduces inertia, enabling high-speed solutions.

Maintenance and Troubleshooting Tips

Regular inspections are essential to maintain the efficiency of Delta robotic kinematics. Special attention should be paid to Delta kinematics and joints. Lubrication of mechanical components with suitable lubricants is crucial for extending the service life of high-speed applications. Checking control components for compatibility with current software updates is also vital. Depending on the application, thorough cleaning is necessary, especially for hygienic models, to meet industrial requirements.

Additionally, preventive replacement of wear parts should be considered to ensure automation functionality and avoid unexpected failures. With professional maintenance and care, Delta robots remain highly efficient and guarantee maximum availability in production.

Future Developments in Delta Robot Technology

With ongoing advancements in automation and AI, Delta robots are continuously evolving. Future developments focus on increasing efficiency, enhancing adaptability, and improving integration with AI-driven decision-making processes. The implementation of machine learning algorithms allows Delta robots to optimize pick-and-place operations dynamically, adapting to changes in production lines with minimal human intervention.

Additionally, new materials and lightweight designs are being explored to further reduce inertia, leading to even higher speeds and improved energy efficiency. As robotics technology advances, Delta robots will become even more versatile, playing a crucial role in smart manufacturing and Industry 4.0.

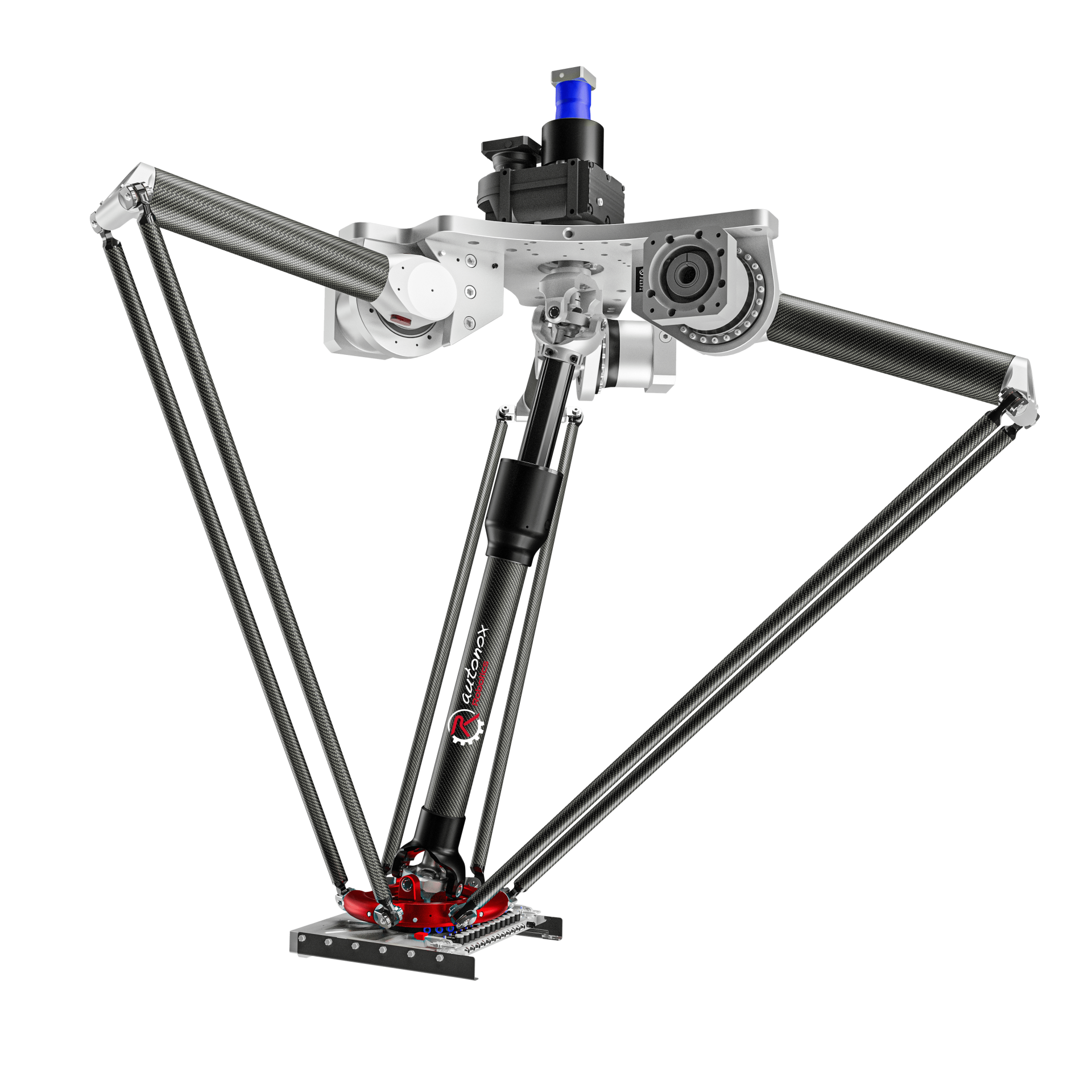

Delta Robots by autonox Robotics

The Delta robots from autonox Robotics set new standards in automation. Thanks to open mechanical designs and unique parallel kinematics, separate controllers are not required, simplifying integration into existing machine platforms and making the mechanics control-independent and in some kind open source.This allows the robot to be integrated like a linear axis directly into the machine architecture without requiring additional control software.

With a portfolio of over 300 parallel and serial kinematics, autonox Robotics offers a wide range of industrial Delta robots. As one of the leading delta robot manufacturers, autonox Robotics provides delta robot arms, delta robot pick-and-place solutions, and even delta robot pick-and-place open-source models for advanced flexibility.

Through the autonox online catalog, users can select degrees of freedom, payloads, workspaces, and other configuration options based on their specific requirements. The delta robot structure is designed to optimize efficiency while reducing mechanical complexity.

From 2 to 6 degrees of freedom – choose the right model for your application!

Discover our autonox Finder. With just a few clicks, filter the ideal product from the world’s largest portfolio of control-independent robot mechanics.